Energy holds an extraordinary status as it plays the key role of the national security and economic lifeline, has once again been elevated to the top political agenda as a result of an energy crisis triggered by the war between Russia and Ukraine. The instability of the international situation has led to fluctuations in oil prices.

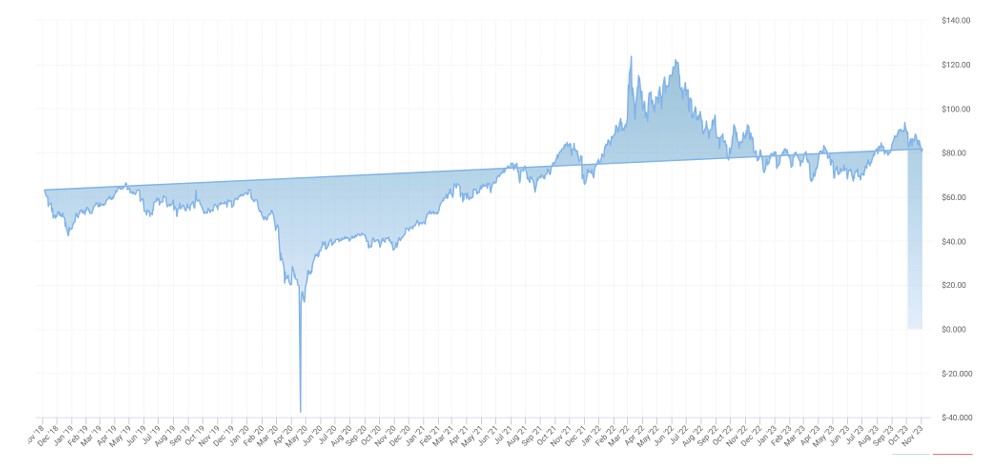

The spike in oil costs, with WTI benchmark rates surpassing $125 per barrel in March 2022 and maintaining a consistently ascending trajectory since is conspicuous, especially considering it plummeted to record negative values just under three years prior. However, the fossil fuel still accounts for over 80% of the global energy consumption, despite its high carbon emission, and resource dependence.

To break away from dependence on fossil fuels, United Kingdom has adopted policy strategies to decarbonize the electricity sector, which accounted for 17% of the total Greenhouse gas emissions in 2023. Zero-carbon power in Britain’s electricity mix grew from less than 20% in 2010 to over 50% in several months of 2022. As renewable energy usage rises, solutions varying in storage capacity and discharge duration are needed to counteract the intermittency inherent in these energy sources, matching supply with demand.

Hydrogen offers the advantage of storing a large amount of energy (1 GWh to 1 TWh) for both intra-day and inter-seasonal storage. Electrolysers produce hydrogen using surplus electricity, which fuel cells later convert back to power during shortages or peak prices. However, hydrogen produced from water electrolysis is costly, ranging from $4.15 to $10.49 per kilogram in 2023, compared to $1.34 to $2.27 per kilogram for steam methane reforming-produced hydrogen. In 2019, the worldwide hydrogen consumption was about 65 million tonnes.

Almost 98% of this hydrogen was produced from carbon-intensive processes, and only 1% of hydrogen produced from water electrolysis[16].To enhance the integration of renewable energy sources, it is imperative to address the high electrolysis costs, which, as a significant impediment due to substantial energy requirements and the capital expenditure . Electrolysis Energy Systems on electrolysers, comprised approximately 40-45% of the overall green hydrogen production expenses as of early 2023.